For the material ABS, there are inkjet printing systems that fulfil the requirements of ink adhesion for consumer appliances.

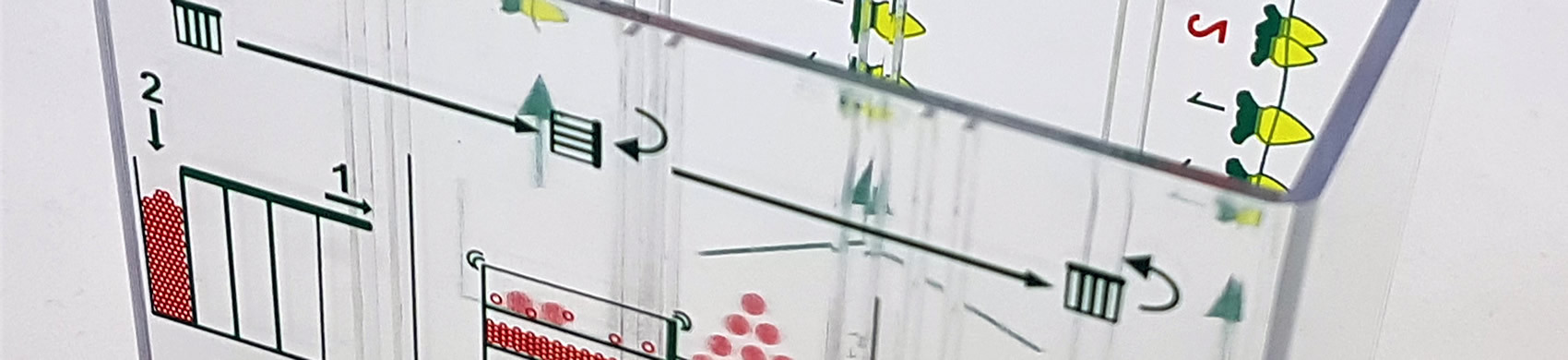

Container printing, housing printing

We print plastic and metal housing, panels, covers and small parts using silk screen printing, pad printing and inkjet printing. Industrial labels are subject to high demands in weather-resistance, surface stability, solvent-resistance and ink adhesion. A special characteristic of the silk screen printing process is the colour thickness which cannot be achieved with any other printing process.

Description

Another feature of silk screen printing is the high pigmentation of the colour that can help to achieve excellent colour brilliance and high ink coverage. Where there are arched surfaces, we print the parts using pad printing.

The following materials can be easily printed in the container printing process:

- Rigid PVC,

- ABS / SAN,

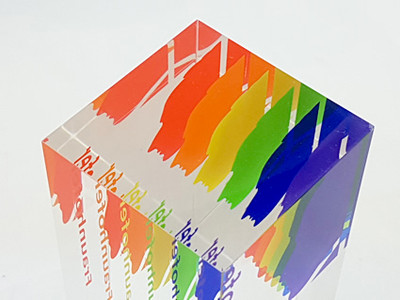

- Acrylic glass (PMMA),

- Polycarbonate (PC),

- Polyester,

- PETG / PETA,

- Thermosetting plastics,

- Thin-layer anodised aluminium,

- Varnished supporting surfaces,

- Polyamide (PA),

- Polyacetal (POM).

Variations an deviations in quality in various delivery batches make it necessary that preliminary printing tests are carried out for every new delivery batch in order to able to guarantee a consistent quality in container printing. As part of the sample approval process, we process sample parts according to customer specifications. The customer checks the print motif, colour, ink coverage, ink adhesion and other quality features based on the sample part.

If the results are within the specifications, the customer gives us the go-ahead to print. The released samples serve as reference samples which we use to assess the quality of printed parts in subsequent batches. Every deviation in the customer’s manufacturing process can result in effects on print quality.

Changes in the customer’s process or by their sub-suppliers must be communicated to us early enough so that we can identify effects on the print quality in our printing process.