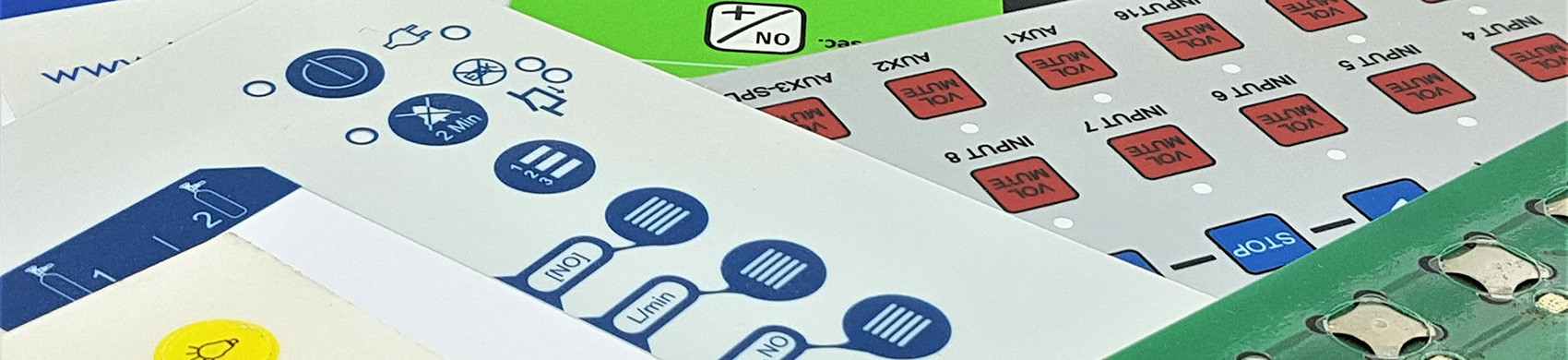

The gradients in the decorative motif are printed with a grid. The key domes are embossed.

Membrane switch overlays

Simplicity is the advantage of membrane switch overlays as compared to classic keyboards with their mechanical construction. Other features include low height, protection of the device’s interior from dirt and moisture, easy cleaning of the membrane switch overlay and abrasion resistance of the keyboard printing through use and cleaning. We produce customised membrane switch overlays for diverse input systems. Membrane switchoverlays are used with both fixed circuit boards (FR-4) and flexible circuit boards (FPC) for input systems. The films developed for this application purpose are back-printed and self-adhesive.

Description

The film material is made from a biaxial-oriented polyester with a UV-hardened, scratch-proof structured (velvet matt/matt) or polished surface.

Typical film thicknesses are 150 µm, 175 µm and 200 µm

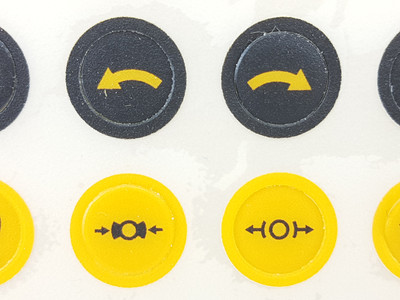

The keypads can either be flat or arched on the membrane switch overlay. The key curvature is achieved by embossing the film or with a cast resin coating (doming procedure) on the keypad.

Dome embossing is used for metal snap shields (also known as metal domes or snap domes) and raised embossing is used for short-stroke buttons.

For improving the haptics on flat membrane switch overlays, raised key edges are recommended or applying a PU dome on the keypads by means of a gas resin coating (polyurethane). The height of the dome is variable, UV-resistant and can be executed in various degrees of hardness.

With the PU domes, a very distinct haptic sensation can be achieved in comparison to the embossed ones, which is particularly necessary when operating the keys with work gloves. The film manufacturers specify values between 1 million and 5 million switching operations until material fractures may occur.

We also produce appropriate spacers for fixing metal snap shields (snap domes, metal domes) or for balancing differences in height when developing the film key.