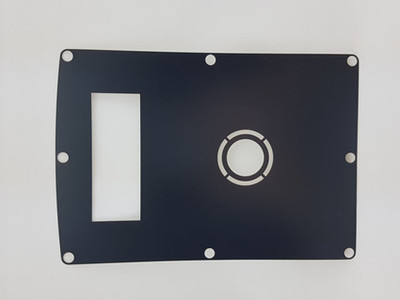

Intermediate layer for front panels, Lexan FR700, UL 94 classified, made as a prototype using a Zünd plotter with close tolerances and fine recesses

Plastic stampings

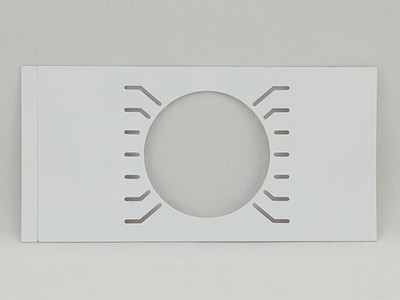

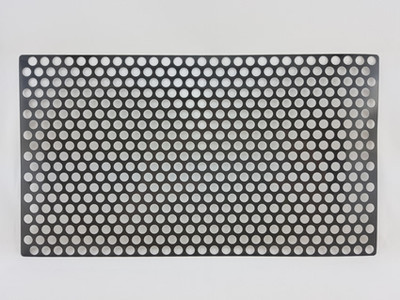

We produce smooth plastic stampings with minimised ridges and in line with ISO 8015 and ISO 2768-mK. We punch, plot, laser and mill films and plotting materials from various plastics. The choice of processing type is based on the plastic material, its thickness and the forms to be saved. The processing of plastics which is virtually free from delay and faults, particularly with regards to recesses which are close together, is one of our unique selling points.

Description

We know how to handle material displacement and produce stampings from film and panel material with a high level of dimensional accuracy. We equip plastic parts with self-adhesion upon request, with partially punched areas and peel-off tabs with material numbers printed on them. We use our Keyence IM 6120 digital measuring projector to check during production if the die-cuts adhere to dimensional tolerances.

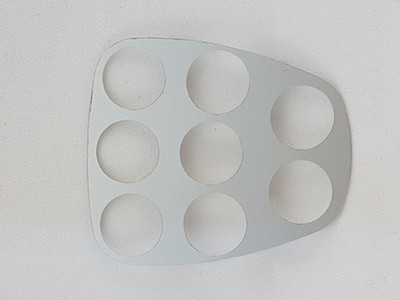

The following are examples of plastic parts produced by us:

- Depositor for joysticks in mini excavators, PC 500 µm

- Templates for fixing vaccination ampoules in the packaging, PETGAG 400 µm

- Water guard films for washing machines, PC 175 µm UL94

- Double-sided, self-adhesive intermediate layer for height adjustment, PC 250 µm

- Diffuser films for backlighting in displays, PC 150 µm

- Splinter-protective films for the packaging of high-pressure mercury lamps

- Splash guard covers, PETGAG175