PMMA acrylic glass is the most used material for control panels. After the manufacturing process, a protective film is applied to both sides.

Control panels, front panels

We process and print control panels from acrylic glass (PMMA) and polycarbonate (PC) and print anodised aluminium panels, stainless steel panels, and painted metal and plastic panels. Front panels and graphic overlays differ in the thickness of the plastic material. We use sheet material (> 1 mm) for front panels and film material (< 1 mm) for graphic overlays. Front panels are attached to panel frames and graphic overlays on panels for appliances.

Description

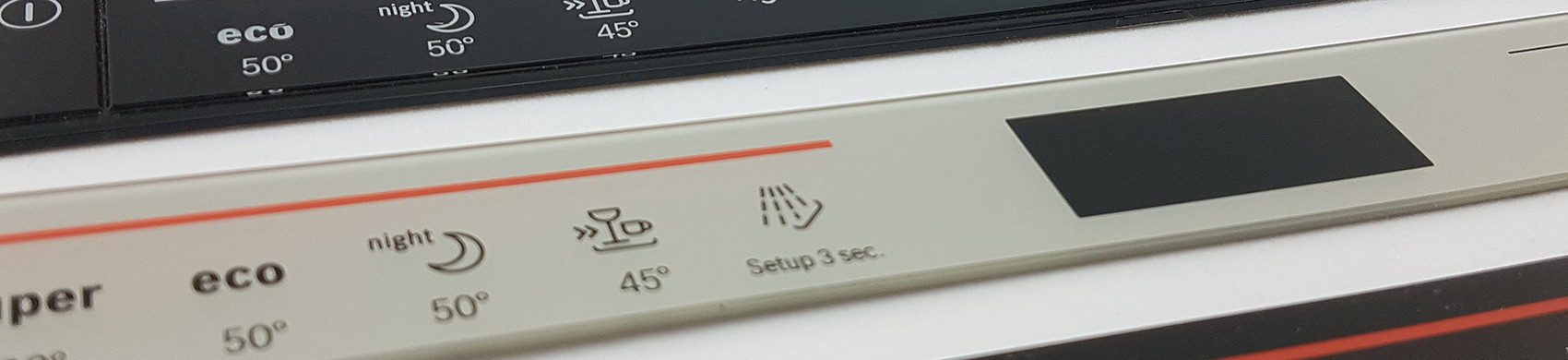

We print plastic panels made from transparent materials on the rear side and partially on the front. The front side has a hard-coated and high-gloss surface. An adhesive film protects the surface from scratches and dirt which can be removed by the customer. We can make the control panels self-adhesive upon request. Reflective colours in silver, gold and other metallic colours can be used. The disappearing effect in the area of the display window and LEDs is another design feature. The writing and symbols are visible when the LEDs illuminate them from behind.

We produce the lettering and symbols under negative pressure or release them from the coloured layer with a laser. By lasering out the lettering and symbols, country-specific variants can be manufactured cost-effectively in batch sizes. Some customers produce the country-specific front panels with a laser themselves synchronously to the manufacturing process, meaning the product variant first emerges in the final assembly.

The range of variants is reduced, the price per unit decreases and the control panels are available more quickly. We print arched control panels using pad printing. We use inkjet colours to print the suitable plastics for inkjet printing. Here, it is important to choose the right inkjet printing system for the material to be printed.

By choosing the right inkjet colour system, the ink adhesion fulfils the requirements of the cross-cutting test film test according to DIN EN ISO 2409.