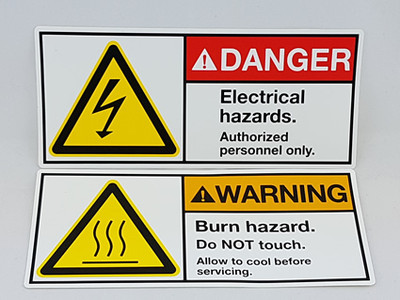

These warning stickers are printed using a thermal transfer printer. The thermal transfer process involves thermally fusing the coating onto the film with a resin ribbon. Colour brilliance and colour stability are even more pronounced than that of the screen printing colours.

Stickers, adhesive labels, domed stickers

We manufacture self-adhesive, printed stickers, labels, signs, symbols and other sources of information needed in industrial manufacturing of durable consumer and industry goods. We advise you on the right films and stickers for your particular operating conditions. We process every printed surface or partial surface with a decorative three-dimensional surface coating known as doming.

Description

We manufacture according to national and international requirements, norms and guidelines, such as ISO 3864, ISO 7010 and ISO 11684, as well as the relevant norms and provisions in line with UL / CSA for export to the USA

With us you get declarations of conformity according to RoHS and REACH for the materials processed by us.

Printed self-adhesive films can be used in all areas of life. The operating conditions and the durability required of stickers differ greatly.

In inkjet printing, printed monomeric calendared films, which are not equipped with permanent adhesive stickers, are the cheapest variant for advertising labels which are to be used indoors for a clear period of time. The service life of these films is around two to three years.

The demands of stickers to be used on vehicles outdoors are opposite to those for advertising labels indoors with regards to durability. For this, cast films with permanent adhesives are used. The adhesives are characterised by a good resistance to chemicals, very high transparency and UV light resistance, as well as by a high resistance to ageing.

The adhesives, which are resistant to temperatures from -40°C to +150°C (to +200°C in the short term) are particularly suited to extreme weather conditions. In order to also reach a printing durability adapted to the film, it is printed either by using the screen printing or thermal transfer printing process. Durability is at least ten years.

For car wrapping, it is necessary to use cast films, as the restoring forces (dimensional stability) of the films otherwise does not allow for long-term adhesion of corrugations and rivets. Corrugations are trough-shaped indentations in metal to increase the stiffness of individual parts or constructions. Cast films can additionally be tempered with a hot-air gun and the low restoring forces can thus be entirely neutralised.

As well as monomeric calendared and cast films, there are also polymer calendared films, whose durability is up to a maximum of six years.

When warning stickers, prohibition signs, mandatory signs, information signs, safety symbols and product safety signs need to be applied to products, the legal consequences need to be clear, which can result from product liability law if the stickers on these products are not legible anymore during their intended period of use or are even lost, leading to an accident at work.

According to product liability law, the manufacture is subject to many different road safety obligations for their product. This also includes instruction errors, such as incorrect or insufficient operating instructions, information and warnings. The manufacturer needs to give warning of all dangers, which are also a threat when products are used as intended. The manufacturer must not assume that the product is used properly by every customer, but must also consider the foreseeable misuse so that liability claims cannot even be made in the first place.

The RoHS guidelines govern usage limits of certain hazardous substances in electrical and electronic appliances.

The REACH regulation governs the registration, evaluation, admission and restriction of chemical substances within the EU and contains provisions with regards to passing on substance information within the supply chain. The aim of the regulation is to guarantee safe handling of chemicals for a better protection of health and environment.